Building on a legacy that began with SPTS Technologies in 1984, KLA has continually invested in the region, most recently with a new $138 million R&D and manufacturing facility in Newport. Their state-of-the-art site supports up to 750 employees and features industry-leading cleanrooms and demonstration labs, enabling close collaboration with customers and partners.

KLA’s Welsh operation sits at the heart of the world-renowned Compound Semiconductor cluster, benefiting from strong links with local universities and a vibrant network of technology companies. The company’s commitment to innovation, talent development, and sustainable growth is helping to drive the sector forward both locally and globally.

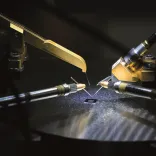

“The demo cleanroom, along with its viewing lobby and adjacent meeting rooms, is designed for customers to engage with our engineers, enabling discussion and alignment over continuous innovation, advancing our next generation of tools and therefore our customers’ technology roadmaps.” Andrew Evans, KLA

KLA’s continued investment is a testament to Wales’ strength both as a destination for pioneering technology businesses and a key contributor to global industry.

To find out more about KLA click here.