Business backstory

Have you ever noticed that, even as the technological products we depend on get more powerful, they also get smaller?

A big reason for this downsizing is the incredible breakthroughs made over the years in computing power particularly with semiconductors. Back in the 1980s, these digital workhorses were considered powerful yet a little cumbersome – as anyone who owned an early mobile phone will attest.

Today, the latest generation of semiconductors can fit 50 billion transistors onto a chip the size of a fingernail. That’s a stunning validation of what within the tech industry is known as Moore’s Law: the observation made by Intel co-founder, George Moore, back in 1965 that the number of transistors on a microchip will double every two years even as the cost of computers will halve.

These incredible breakthroughs have allowed the integration of microchip computing to transform nearly every area of business and modern life. But with progress comes new challenges – namely, how to apply and integrate this tiny tech safely and securely into all the products and places it is required?

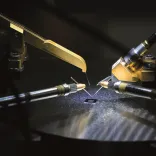

That’s where Microchip Technology Caldicot comes in. The South Wales-based subsidiary of the US semiconductor giant specialises in advanced packaging solutions – working with customers on the design, rapid prototyping and manufacturing of specialist and very small protective modules for semiconductor chips.

“We specialise in miniaturisation and that’s what really separates us from other companies in our sector,” says Rhys Waite, business and technology development manager at Microchip.

“Compound semiconductors really underpin the high productivity drive and the direction of new products – whether that be in the areas of renewable energy, electric vehicles or higher efficiency. So we see a lot of opportunities for growth in this sector,” he says.

The Caldicot operation currently employs 130 employees and is experiencing both growth and great interest across many sectors. These include healthcare (where the company works on pacemakers and other digital personal health products) and telecommunications (where it is developing modules that can withstand high temperatures, high power and other harsh environments). The company also is developing innovative applications for the space, aviation, defence and automotive industries.

Why Wales?

Given the complexity and high skill levels needed, it’s not surprising that Microchip puts a premium on its relationships with local universities and the ability to tap into Wales’ proven academic high-tech expertise.

“Naturally, we are biased toward tech skills to support our business,” says Waite. “We are involved in several collaborative projects with local universities – we like to call them our virtual tech family. This gives us access to leading edge research and some very senior academics.”

Microchip also is one of 12 partners in the UK Research and Innovation-funded CSconnected – a £43m project to create the world’s first compound semiconductor community by building on Wales’ strengths in manufacturing new and emerging hardware.

As Microchip projects ever greater growth over the coming years it will look to cement its already strong relationship with academia, government and industry partners. That way, even as the semiconductors of the future get smaller, the influence of the industry on Wales will continue to increase.

Learn more about Microchip on the Microchip website.