It’s a unique partnership of universities, research centres and innovative companies, all driving forward the technology to power the next industrial revolution.

When explaining the potential of compound semiconductors, Sam Evans of Newport Wafer Fab uses a simple analogy. “The first industrial revolution relied on steam,” he says. “That made the magic happen.

Today, compound semiconductors are the steam – the enabling power – for what’s being called the fourth industrial revolution. And we have all the process knowledge to create that steam in Wales.”

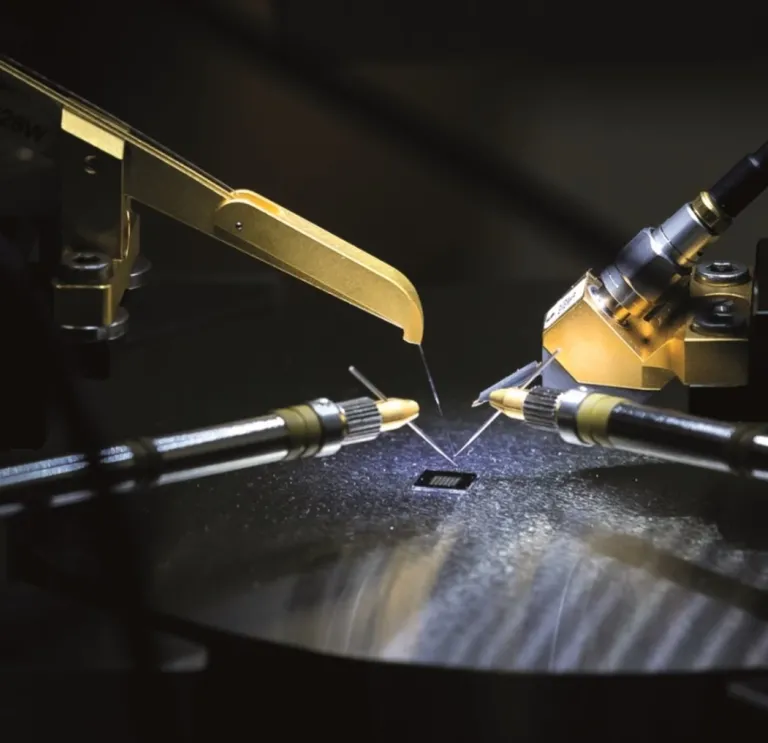

Compound semiconductors are atomically engineered materials that enable high-speed processing hundreds of times faster than current silicon technologies. They’re already all around us – in fibre optic communications, in digital media and sensing, including 3D face recognition, and in the circuitry of almost every smartphone. But as the latest technological revolution promises to turn both work and leisure upside down, their importance can scarcely be overstated.

“We’re talking about applications like 5G communications and artificial intelligence, or enabling truly autonomous vehicles,” says Kevin Crofton, president of SPTS and chairman of the Compound Semiconductor Applications Catapult.

“These types of applications demand very highspeed transmission rates to allow instantaneous decision-making. When a driverless vehicle needs to decide how to avoid an impending accident or whether there’s a pedestrian in front of it, you can only afford nanoseconds of delay in decision making and action.”

The South Wales cluster, branded as CSconnected, brings together research and development competence and industry expertise with almost a complete supply chain in a very concentrated geographical area. Four companies are involved as collaboration partners: IQE, which makes the wafers; Newport Wafer Fab, which processes the chips; packaging specialists Microsemi, a wholly owned subsidiary of Microchip Technology; and SPTS, which makes the equipment used in manufacture.

They work closely with the five development partners – organisations and institutions directly involved in R&D and innovation. Core research is carried out at the Institute for Compound Semiconductors at Cardiff University, which will be joined by Swansea University’s Centre for Integrative Semiconductor Materials. Product, services and skills development are the responsibility of the Compound Semiconductor Centre (CSC) – a collaboration between IQE and Cardiff University that offers cutting-edge facilities to help researchers and industry work together. The Compound Semiconductor Applications Catapult focuses on helping the industry sector to exploit the advances made by researchers in key areas such as healthcare, the digital economy, energy and space. Lastly, a Future Compound Semiconductor Manufacturing Hub will conduct research into large-scale manufacture of the devices.

It’s an impressive offering, and one that has attracted significant investment from research investment funds and government at regional, Welsh and UK level. “We see the power in clustering and having regional capabilities, just like Silicon Valley in the 1960s,” says IQE’s Chris Meadows.

“Once you’ve reached a critical mass, you get what I like to call the Hay-on-Wye effect. You may think, ‘Why would you have so many bookshops competing with each other?’ but the point is that people know there are lots of bookshops, so they all go there.

“It’s the same with Silicon Valley. It attracted people into the region because they knew they could build a career – they could move from one company to another. And it provides opportunities to grow the cluster. Not only do you attract people in, you attract further elements of the supply chain.”

Jim Ryan, director of worldwide module operations at Microsemi, a subsidiary of Microchip Technology, agrees. “It’s why we wanted to be part of the cluster,” he says. “We could see a real opportunity for Wales if it offered fully integrated semiconductor solutions for customers in a one-stop shop. It means we can grow Wales’ economy by many times what would be possible if all we did was produce the chips themselves.”

And for the foreseeable future, the South Wales cluster is likely to remain the only one of its kind. Kevin Crofton says: “There isn’t a region in the world right now that has the breadth of compound semiconductor capability that exists here. If we can attract and retain talent, and get the educational systems aligned with our vision, we’ll be a centre of excellence for the world – not just for the UK or Wales.

“It could be a worldwide phenomenon. We have the potential. We could evolve into a Silicon Valley for the compound semiconductor arena.”

*Content accurate at time of publishing*