It began with an urgent phone call from the National Health Service (NHS). ‘We’ve got a problem,’ they said. ‘Our Intensive Care Unit is running out of PPE. Anything you can do to help?’

In March 2020, as the first wave of Covid swept across the world, healthcare systems were buckling under the pressure. There weren’t enough beds, medicines, ventilators or PPE (personal protection equipment).

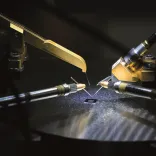

Rototherm has made a lot of clever stuff over the past 170 years. Our core business is manufacturing sensors: high-precision instruments that measure pressure, temperature and level. You’ll find our kit all around the world in nuclear submarines, pipelines and pharmaceutical plants. We make the probes that measure the density of Tsingtao beer, and the temperature of IKEA’s meatballs. But PPE? No. But we were ready to try.

We put a small team together, made ten face visors, and sent them to the NHS. A couple of days later, the phone rang again. ‘Great, thanks. Can you make us another thousand?’ So we did. Another phone call. ‘Any chance of 100,000?’ Within a month, we were making a quarter of a million CE-certified visors every week. And that was just the start.

By May 2020, we’d bought machines to make disposable face masks, and built a cleanroom to put them in. Soon we had the second-largest mask manufacturing line in the UK, with a capacity for 13 million masks. We worked with the Welsh Government to create a reusable mask that’s now supplied to every school in Wales. The French company Bollé asked if we could make their safety goggles. At one point we had an extra 300 staff on site, on top of the 120 we already had.

In six months, Rototherm had changed almost beyond recognition. But actually, the change had been happening for a decade. We had the culture right. We were ready. We were agile. We were Lean.

I’ve always been fascinated by the concept of ‘operational excellence’. I used to work for a Japanese conglomerate, and they have an insanely amazing attention to detail. We’ve applied those principles to Rototherm. We try and get a little bit better every day. For instance, everyone spends the first half-hour of every day making an improvement, no matter how small. It might be something as simple as fixing a door handle. Twice a week, we hold a morning meeting for the whole company. We don’t just talk about the work stuff: sales targets and supply chains. The first question we ask is: what are you grateful for today? It could be something as simple as the sun shining. If you feel a sense of gratitude for that, you’ll feel happier. And happier people tend to make better quality products, which makes for happier customers.

Here's another thing: I clean the factory toilets. Not just me - everyone does. We’re all on a rota for cleaning the loos and canteen. Not only is everything spotless all the time, but everyone feels that sense of respect: for the company, for each other, for themselves.

We share operational excellence by posting videos on YouTube, and inviting people to visit the factory and see what we’re up to. I used to worry about giving away ideas to competitors, but it’s actually a good way of keeping us moving forward. That great idea we had yesterday? We’ll have a better one today. And our openness turned out to have other benefits: one of those organisations who visited us, just before the pandemic, was… the NHS.

The pandemic has thrown a welcome spotlight on manufacturing. It’s shown how valuable the sector is, but also how fragile international supply chains can be. I think the UK has tilted too far towards a service economy, but Wales is lucky to have held on to its manufacturing base. A few companies recently got together to form Manufacturing Wales, because we thought it’s crazy that so few people know how good Welsh manufacturing is.

We’re a diverse bunch, including the Penderyn whisky distillery and compound semiconductor experts IQE and SPTS. There’s Creo Medical, who specialise in very small medical devices, and Pro Steel Engineering, who make very big metal things. We’re pulling together Welsh manufacturing firms and academia to connect, share ideas, solve problems and create new ventures. There are so many companies here that are well-run, high-quality and super-agile. Coronavirus has pushed us all to invest in new machinery, digital capabilities, robotics and green technologies.

A year ago, I’d never have been able to predict what I’m doing today. But I can tell you what I’ll be doing tomorrow: getting a little bit better, every single day.

To discuss opportunies in this secter contact us here